JETvarnish 3D

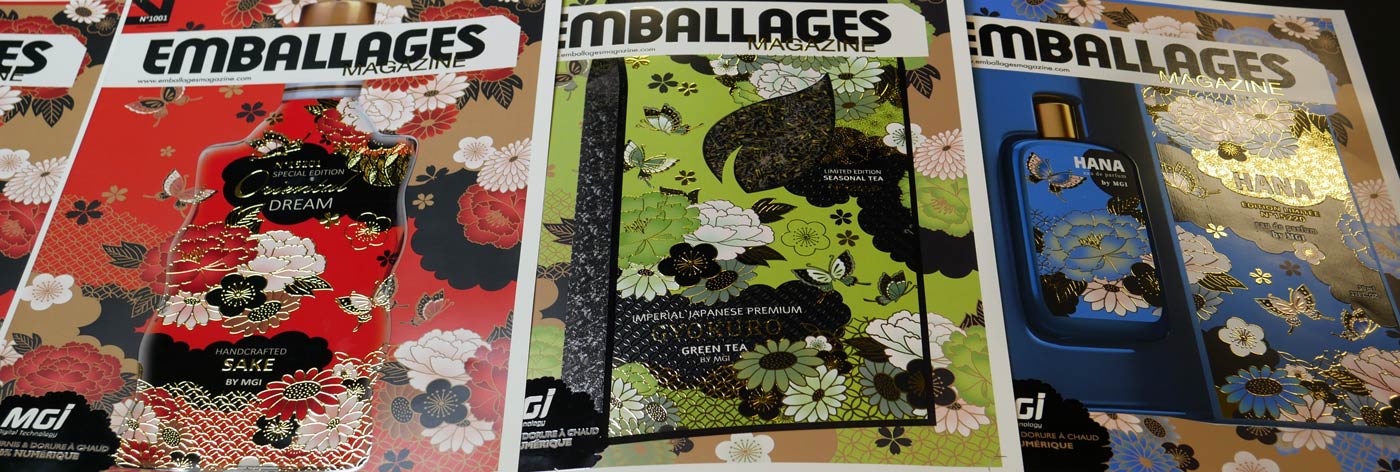

The most versatile digital selective varnishing and hot foil stamping solution on the market.

Its B2 format corresponds to the core of the commercial printing market. JETvarnish 3D is the most sold press in the world on the market and delivers high-end services with or without 3D relief. JETvarnish 3D manages all formats up to 64 x 120cm.

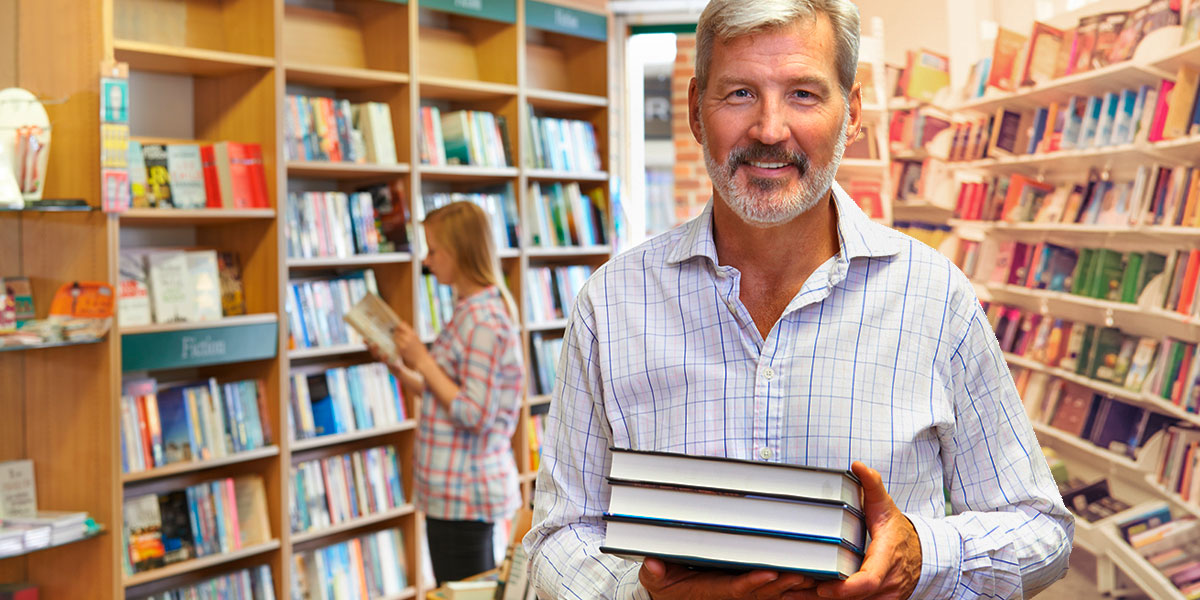

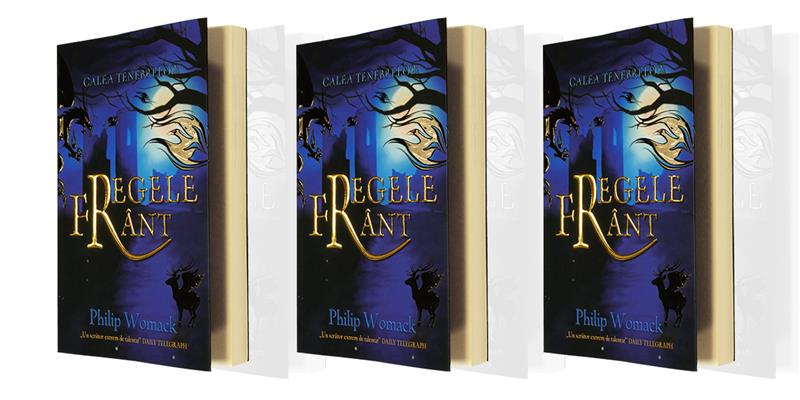

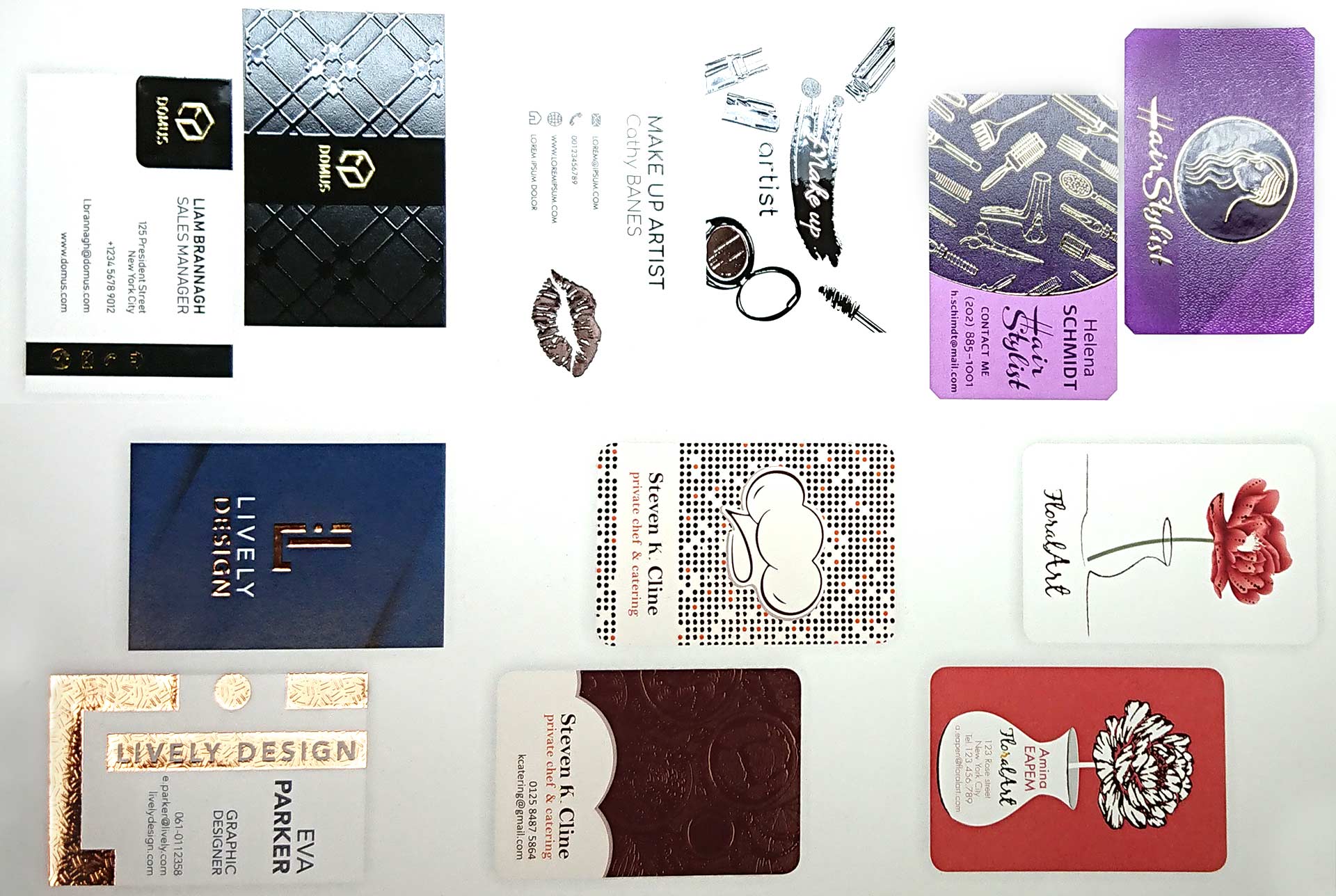

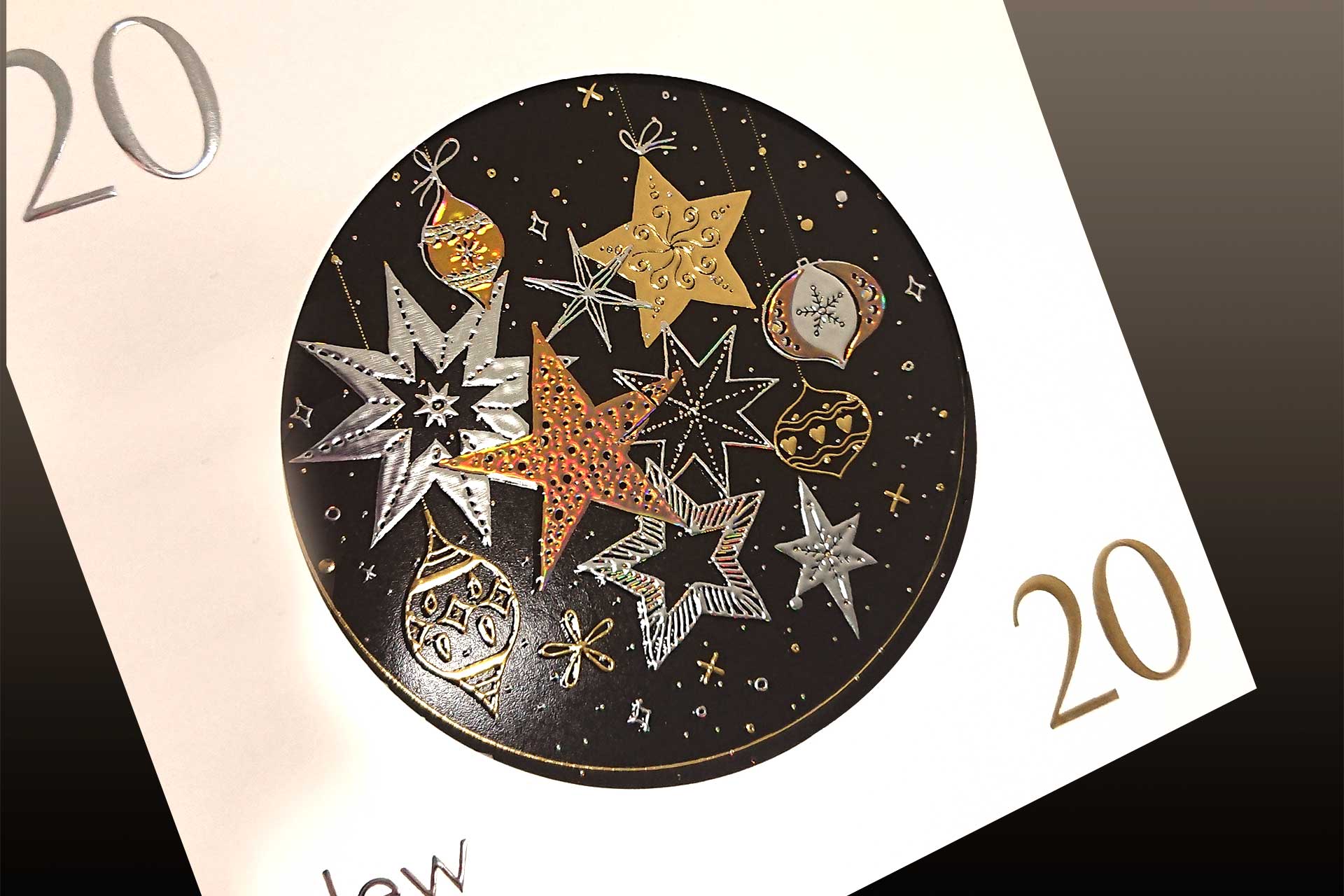

The JETvarnish 3D is designed to process digital and offset prints. Its versatility allows you to process prints ranging from A4 to 64×120 cm, from 1 to several thousand copies. Win new prospects and profitable markets. Your customers will discover with amazement, the incredible quality of a selective varnish with or without 3D relief effect. Sublimate their prints!

JETvarnish 3D is mainly used to ennoble book covers, invitation and business cards, brochures, packaging, leaflets and wrappers.

General characteristics

Formats

- Min : 21 x 29,7cm (width x length)

- Max : 64 x 120cm (width x length)

Sheet weight

- Min: 135g/m² (or 150 µm) before printing and lamination

- Max: up to 800g/m².

Compatible with solid board

Margin

- High capacity feeder that can accommodate a stack of sheets up to 60 cm high for 52 x105cm sheets

- Approximately 4,000 sheets of 135 gsm paper

Recipe

- High capacity stacker that can accommodate a stack of sheets up to 60 cm high for 52 x105cm sheets

- Approximately 4,000 sheets of 135 gsm paper

Substrates

- Direct application of the 3D coating on most of the(1) matt or glossy coated surfaces, with or without acrylic varnish, coated paper, plastic, PVC and other closed synthetic materials

- Direct application of the 3D coating on some(1) digital toners (e.g. MGI Meteor)

Paper path

- Pneumatic derailing

- Double sheet detection cell

- Flat track and variable suction belt transport

Selective UV inkjet

General

- UV inkjet developed by MGI

- Drop-on-Demand (DoD) technology

- Piezo heads. Single pass printing

- Modular and scalable printing architecture

Production speed

Up to 3,123 B2 ISO per hour (2D coating) (2)

Printing width

- 51 cm (standard)

- 54 cm (extended) with optional feeder and L or XL pallet recipe

Varnish thickness

The user can vary the thickness of a varnish from 3 microns (µm) identical to a traditional selective varnish, to an impressive 200 (µm) that you can literally feel under your fingers.

Tracking

- Motorized left and right margin table. Automatic registration via AIS SmartScanner as standard for full sheet scanning in real time.

- Tolerance ± 200 microns

Digital hot stamping

Production speed

Up to 1750 B2 sheets per hour (or 25 m/min) (2)

Maximum area

The useful surface of gilding cannot exceed 51 x 104cm (standard) or 54 x 118cm with the option loader and pallet recipe

Embossing

Hot stamping with embossing for a 3D effect. Metallized films can be covered with a layer of varnish for protection or aesthetic reinforcement

Films

Film consumption optimization system

Stamping coils

- Maximum roll diameter and length: ± 30cm and from 400 to 2000 meters of film.

- Up to 3 rolls of film can be loaded simultaneously with a width of about 10cm

- 2 chucks available: 1 inch and 3 inches

Other options

Pallet loader L or XL

Sheets up to size 57 or 64 x 120cm

Corona treatment (3) (4)

In-line system designed to optimize coating adhesion on complex printed substrates

L or XL pallet recipe

Sheets up to size 57 or 64 x 120cm

Variable data WTP

- Management and modification of files on the workstation

- Complete variable data (text, graphic, image) for selective varnishing and gilding areas.

- Integrated barcode reader (1D / 2D)

- Optional Raster Image Processor (RIP)

Dimensions

- Dimensions (W x D x H) & weight: from 8.03 to 12.72 x 1.76 x 1.81m(5)

- Necessary clearance: 1m on all 4 sides

- Up to ± 4 278 kg(5)

(1) contact MGI to check compatibility with your substrates / lamination / toner / acrylic varnishes

(2) the speed varies according to the parameters used

(3). recommended on substrates larger than 42cm width

(4) recommended on papers over 250g / 250µm

(5) depending on the chosen configuration